|

|

Tape Strong:ST-630-ST-5400 Width(mm):600-2600

|

A、Usage

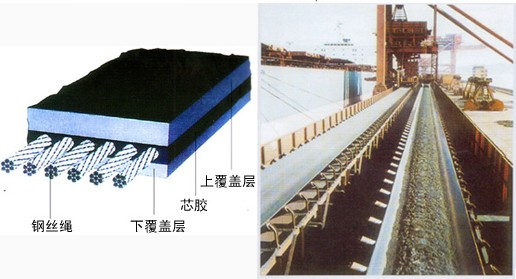

Steel cord conveyor belts are widely used in high strength , long distance and heavy load transportation of

materials, and they are also used ini high strengh and short distance transpostation of materials on specail

occasions.

B、Characteristics

1. High tensile strength: The belts are suitable for large span , long distance transportation of materials

2. Small elongation in use: The belts need only a very short take-up stroke distance.

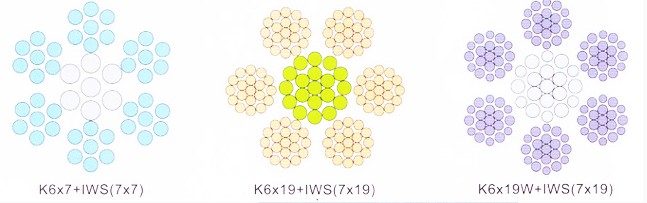

3. Small diameter of drive pulley: The belt body has a layer of longitudnally arranged steel cords as its skeleton,

and thus is flexble and fatigue - resistant. Therefor, drive pulley of smaller diameter can be used to make the

equipment smller

4. High adhsion between rubber and steel cord: The steel cords are coated with zinc on their surface, and also

the rubber has the property of good adhesion with steel cords , Therefore the rubber is tightly adhered to the

steel cords that is shock resistant and hard to peel off, which make the belt long life.

5. Even tension of steel cords: Out of our advanced techniques in manufacturing , the steel cords are very equably

arranged and have the same tension ,so the belts are well balanced in running and difficult to run away.

6. Good throughability: As the belt body has no transverse skeleton, it is easy to form a deep trough , so the beltscan load more materials and prevent the materials from escaping.

7. Inspection of the belt with X-rays: Users can use X-rays to inspect damages of the skeleton , the steel cords onthe conveyor machines to prevent accidents. |

| Technical parameters: |

| Tensile body optional high-intensity, low-extension of galvanized copper丝绳, core rubber adhesion with a rope, and fatigue-resistant, anti-aging, good elastic rubber, plastic covering selected high strength, wear-resistant, anti-aging rubber composition. |

| Specifications Model: |

| Strength specifications:630N/mm—5400N/mm Widthspecifications:800mm—2000mm |

|

Specifications

|

ST

630

|

ST

800

|

ST

1000

|

ST

1250

|

ST

1600

|

ST

2000

|

ST

2500

|

ST

3150

|

ST

3500

|

ST

4000

|

ST

4500

|

ST

5000

|

ST

5400

|

|

Longitudinal tensile strength(N/mm)

|

630

|

800

|

1000

|

1250

|

1600

|

2000

|

2500

|

3150

|

3500

|

4000

|

4500

|

5000

|

5400

|

|

Nominal diameter of the largest wire rope mm

|

3.0

|

3.5

|

4.0

|

4.5

|

5.0

|

6.0

|

7.2

|

8.1

|

8.6

|

8.9

|

9.7

|

10.9

|

11.3

|

|

Spacing Wire Rope

(mm)

|

10±1.5

|

10±1.5

|

12±1.5

|

12±1.5

|

12±1.5

|

12±1.5

|

15±1.5

|

15±1.5

|

15±1.5

|

15±1.5

|

16±1.5

|

17±1.5

|

17±1.5

|

|

Cover layer thickness (mm)

|

5

|

5

|

6

|

6

|

6

|

8

|

8

|

8

|

8

|

8

|

8

|

8.5

|

9

|

|

Under the cover layer thickness

(mm)

|

5

|

5

|

6

|

6

|

6

|

6

|

6

|

6

|

8

|

8

|

8

|

8.5

|

9

|

|

Width specifications

(mm)

|

Wire Rope root number

|

|

ST

630

|

ST

800

|

ST

1000

|

ST

1250

|

ST

1600

|

ST

2000

|

ST

2500

|

ST

3150

|

ST

3500

|

ST

4000

|

ST

4500

|

ST

5000

|

ST

5400

|

|

800

|

75

|

75

|

63

|

63

|

63

|

63

|

50

|

50

|

50

|

|

|

|

|

|

1000

|

95

|

95

|

79

|

79

|

79

|

79

|

64

|

64

|

64

|

64

|

59

|

55

|

55

|

|

1200

|

113

|

113

|

94

|

94

|

94

|

94

|

76

|

76

|

77

|

77

|

71

|

66

|

66

|

|

1400

|

133

|

133

|

111

|

111

|

111

|

111

|

89

|

89

|

90

|

90

|

84

|

78

|

78

|

|

1600

|

151

|

151

|

126

|

126

|

126

|

126

|

101

|

101

|

104

|

104

|

96

|

90

|

90

|

|

1800

|

|

171

|

143

|

143

|

143

|

143

|

114

|

114

|

117

|

117

|

109

|

102

|

102

|

|

2000

|

|

|

159

|

159

|

159

|

159

|

128

|

128

|

130

|

130

|

121

|

113

|

113

|

Note: 1, covering thickness, wire rope and wire rope pitch diameter can be produced in accordance with user requirements consultations.

2, according to user requirements using the German DIN22131, Australia AS133, Japan JISK6369 standard production. |

|

Main technical indicators:

|

| 1. Covered plastic properties |

|

Item

|

Performance Indicators

|

|

H

|

D

|

L

|

|

Tensile strength

|

Mpa≥

|

24.0

|

18.0

|

15.0

|

|

Elongation at break

|

%≥

|

450

|

400

|

350

|

|

Wear volume

|

mm3≤

|

120

|

100

|

200

|

| 2. Interlaminar bonding strength |

|

Strength specifications

|

Adhesive strength of wire rope

|

Strength specifications

|

Adhesive strength of wire rope

|

|

Thermal Aging ago

|

After thermal aging

|

Thermal Aging ago

|

After thermal aging

|

|

ST630

|

60

|

55

|

ST2150

|

140

|

130

|

|

ST800

|

70

|

65

|

ST3500

|

145

|

140

|

|

ST1000

|

80

|

75

|

ST4000

|

150

|

145

|

|

ST1250

|

95

|

90

|

ST4500

|

165

|

160

|

|

ST1600

|

105

|

95

|

ST5000

|

175

|

170

|

|

ST2000

|

105

|

95

|

ST5400

|

180

|

175

|

|

ST2500

|

130

|

120

|

|

|

|

|

|

|

|